- Product Detail

- Product Tags

Overview

Cooling circulating water system is a broad concept, including temperature system, heat transfer system and other applications, mainly for different process applications.

Definition

It refers to a water supply system that exchanges cooling water for hot water and cools it down before recycling it. It includes two types: open and closed. It consists of cooling equipment (including cold sources, chillers, cooling towers, etc.), water pumps and pipes.

Principle

A cooling water system that uses water as a cooling medium and circulates it. It is mainly composed of cooling equipment (including cold source, chiller, cooling tower, etc.), water pumps and pipes. After the cold water flows through the production equipment that needs to be cooled (often called heat exchange equipment, such as heat exchanger, condenser, reactor), the temperature rises. If it is discharged immediately, the cold water is only used once (called direct cooling water system). When the heated cold water flows through the cooling equipment, the water temperature drops and can be pumped back to the production equipment for reuse. The amount of cold water used is greatly reduced. Cooling equipment can be divided into open and closed types, so circulating cooling water systems are also divided into open and closed types. The design and operation of open systems are more complicated.

(1) Open cooling water system

Cooling equipment includes cooling pools and cooling towers, both of which mainly rely on water evaporation to reduce water temperature. Furthermore, cooling towers often use fans to promote evaporation, and cooling water is often blown away. Therefore, open circulating cooling water systems must be replenished with fresh water. The flow rate is often determined based on the circulating water concentration limit. Usually, the amount of replenished water exceeds the amount of water lost by evaporation and wind, so some circulating water (called wastewater) must be discharged to maintain the balance of water volume. Circulating cooling water system. In an open system, dust, microorganisms, etc. enter the circulating water due to the contact between the water flow and the atmosphere; in addition, the escape of carbon dioxide and the leakage of materials in the heat exchange equipment also change the water quality of the circulating water. For this reason, the circulating cooling water often needs to be treated, including sediment control, corrosion control and microbial control. The determination of the treatment method is often related to the amount and quality of the replenished water, and also to the performance of the production equipment. When using multiple reagents, it is necessary to avoid possible chemical reactions between the reagents.

(2) Closed circulating cooling water system

Closed circulating cooling water system is also called closed circulating cooling water system. In this system, the cooling water is not discharged immediately after use, but recycled for reuse. The open evaporation system is a cooling system with a wide range of applications and types. It also uses water cooling to remove the heat emitted by the process medium or heat exchange equipment, and then evaporates part of the hot water when the hot water is in direct contact with the air, so that most of the hot water is cooled and then recycled. Therefore, such a system is also called an open circulation cooling water system. It can be divided into many types according to the different ways of contact between hot water and air.

Several structural forms of process cooling circulating water system

1. Cooling tower Cooling water tower

A cooling water tower is a device for cooling water, in which water exchanges heat and mass with the air flowing through it, causing the water temperature to drop; it is widely used in air conditioning circulating water systems and industrial circulating water systems. Under certain water treatment conditions, the cooling effect is one of the important performances of the cooling tower. When selecting a cooling tower, the main consideration is whether there are special requirements for the cooling degree, cooling water volume, and wet bulb temperature. It is usually installed in a place with good ventilation.

2. Heat exchanger unit The heat exchanger unit is composed of a heat exchanger, a temperature control valve group, a steam trap group (when the heat medium is steam), a circulating pump, an electric control cabinet, a base, a pipeline, a valve, an instrument, etc., and can be equipped with an expansion tank, water treatment equipment, a water pump frequency conversion control, a temperature control valve, a remote communication control, etc., to form a complete heat exchange station. The heat exchanger unit has a standardized and modular design, complete configuration, easy installation, and high efficiency and energy saving. The heat exchanger unit has the advantages of compact structure, reliable operation, simple and intuitive operation, etc., and is a ** high-efficiency and energy-saving product. This product is suitable for sanitary hot water in residences, offices, factories, mines, hospitals, hotels, schools and other places. The integral heat exchanger can be used for both water-water exchange and steam-water exchange.

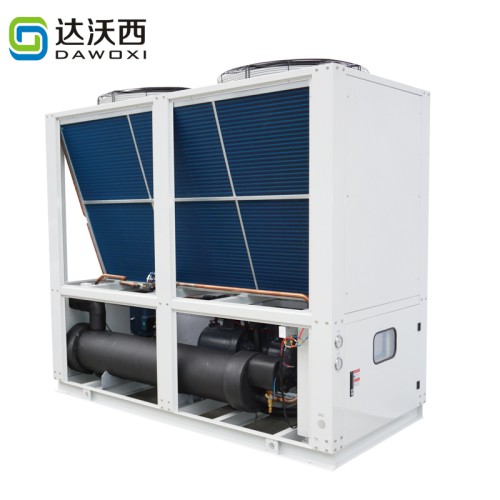

3. Chiller The chiller consists of four main components: compressor, evaporator, condenser, and expansion valve, thus achieving the refrigeration effect of the unit.