- Product Detail

- Product Tags

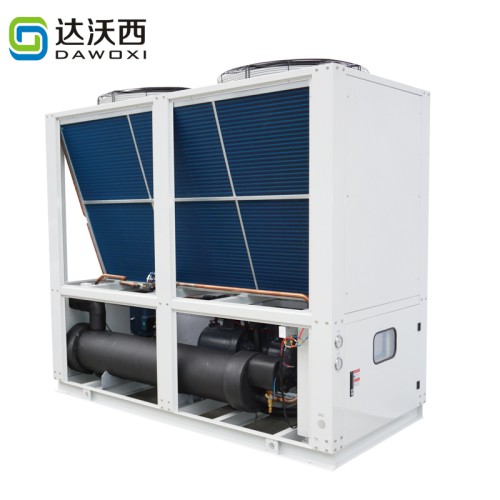

Product Series

Model: DW-CS series

Type: Air-cooled

Cooling capacity range: 2.5KW~135KW

Temperature control accuracy: ±1℃

Temperature range: 5℃~35℃

Water pump pressure: 2Kg~8kg (customized according to demand)

Customizable: Yes

Delivery time: 20 to 40 working days

Note: Some series of products in this series have obtained the overall explosion-proof certificate

Introduction of explosion-proof chiller

1. Chillers are sometimes often used in areas with flammable dust, gas or chemical industry. At this time, the chiller needs to be explosion-proof in the electronic control, motor, fan and other places for safety. Chillers, industrial chillers, freezers, screw chillers, Davosi chillers select world-famous compressors (Germany Bitzer, Taiwan Hanbell, American Copeland), explosion-proof water-cooled units are new units designed spontaneously based on standard chillers. It adopts a variety of explosion-proof methods such as flameproof, increased safety, intrinsic safety, positive pressure, oil filling, sand filling, spark-free, casting and airtight, so that the unit can be used in flammable and explosive places, and different explosion-proof levels can be selected according to the characteristics of the use occasion and different safety requirements.

2. The performance of the unit has passed the professional inspection of the national inspection system and meets the requirements of standards such as EXDIIBT4 and GB/T 18430.1-2007 "Vapor Compression Cycle Chiller (Heat Pump) Unit Part 1: Chiller (Heat Pump) Unit for Industrial or Commercial Use and Similar Purposes"; the explosion-proof performance of the unit meets the relevant provisions of standards such as GB3836-2000 "Electrical Equipment for Explosive Gas Atmospheres" and IEC60079-1991 "Electrical Equipment for Explosive Gas Atmospheres".

3. All chillers of Dawoxi Company are selected from imported famous brand semi-hermetic screw and semi-hermetic reciprocating compressors. The twin-screw 5:6 gear ratio and advanced linear design are low-carbon, energy-saving and environmentally friendly; good performance and low noise. According to customer needs and refrigeration tonnage, single or multiple units are used. The compressor can automatically alternate according to load changes to balance the operating hours of each compressor, greatly extending the service life of the chiller, and trouble-free operation can reach more than 45,000 hours. Screw chiller, chiller, industrial chiller, freezer

Product features

1. The temperature control system adopts a microcomputer controller with a simple and elegant interface, intuitive and easy operation, and various operating indication conditions are clear at a glance. The wide temperature range is 5℃~35℃ and can be adjusted arbitrarily.

2. The core component compressor adopts internationally renowned brands such as Denmark DANFOSS, Japan Sanyo, Daikin, and the United States Copeland, which is a reliable guarantee for the operation of the unit.

3. The core refrigeration accessories are made from international brand components such as Danfoss from Denmark, Emersonguo from the United States and domestic top suppliers.

4. The pipe connection system can be configured according to customer requirements, using materials such as galvanized pipes, plastic pipes, and stainless steel.

5. Fluid equipment adopts well-known domestic brands, such as: Hangzhou Nanfang, Denmark Grundfos, Germany Wilo, Hangzhou Xinjie or imported brand water pumps or special customization according to process requirements.

6. The electrical appliances adopt internationally renowned electrical components such as LS Schneider Siemens Omron, etc., and no special machine room is required.

7. It has its own cooling system, cooling water pump, freezing water pump and water tank, which is easy to move and can be used immediately after it is turned on. It is suitable for areas with scarce water resources and mobile occasions.

8. The fully automatic intelligent control system controls water temperature, ultra-high temperature alarm, water flow, fault signal alarm output, and can be customized for remote control

9. It can meet the demand for process cooling source in 24-hour continuous and uninterrupted production in industrial production.

Note: The company provides on-site selection in the early stage to assist customers in choosing the appropriate machine model and process planning.

Note: The technical parameters are common to various types of chillers and will not be listed repeatedly in this column. Since explosion-proof chillers are non-standard customized machines, please contact sales staff for details!

Technical parameters

| model | DW-1AF | DW-2AF | DW-3AF | DW-5AF | DW-8AF | DW-10AF | DW-15AF | DW-20AF | DW-25AF | DW-30AF | DW-40AF | DW-50AF | ||

| Cooling capacity | KW | 2.7 | 5.4 | 8.1 | 13.5 | 21.6 | 27 | 40.5 | 54 | 67.5 | 81 | 108 | 135 | |

| Kcal/h | 2322 | 4644 | 6966 | 11610 | 18576 | 23220 | 34830 | 46440 | 58050 | 69660 | 92880 | 116100 | ||

| Total Power | KW | 1.1 | 1.9 | 2.7 | 4.9 | 7.3 | 9.2 | 12.8 | 18 | twenty two | 27 | 35 | 46 | |

| Operating current | A | 6.5 | 10 | 9 | 12.5 | 15 | 19 | 26 | 38 | 47 | 58 | 75 | 90 | |

| power supply | 1PH220V 50Hz (60HZ) 110V 50HZ (60HZ) | 3PH 380V50Hz 200V/220V/415V 50Hz(60Hz) | ||||||||||||

| Temperature control range | ℃ | 5~35 | ||||||||||||

| Temperature control accuracy | ℃ | ±1 | ||||||||||||

| refrigerant | type | R22 (R407C/R410A/R134A) | ||||||||||||

| Filling amount | KG | 0.6 | 1.1 | 1.6 | 2.7 | 4.2 | 5.3 | 7.8 | 10.5 | 14 | 18 | twenty two | 26 | |

| compressor | Control method | Capillary | Thermal balance expansion valve | |||||||||||

| form | Piston | Vortex | ||||||||||||

| power | KW | 0.75 | 1.5 | 2.2 | 4 | 6 | 7.5 | 11 | 15 | 18.5 | twenty two | 30 | 37.5 | |

| Water tank | Water tank capacity | L | 28 | 28 | 38 | 65 | 150 | 180 | 285 | 285 | 400 | 400 | 480 | 550 |

| Water tank material | Pipeline centrifugal water pump (SUS304 stainless steel) | |||||||||||||

| Water Pump | Yang Cheng | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| power | 0.37 | 0.37 | 0.37 | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 4 | ||

| Evaporator | type | Water tank coil type (shell and tube/plate evaporator) | ||||||||||||

| Chilled water flow | m3/h | 0.6 | 1.4 | 2 | 3.2 | 5 | 6.2 | 9 | 12.5 | 16 | 18 | 26 | 30 | |

| Condenser | type | High efficiency copper tube plus aluminum foil fin type + external rotor cooling fan | ||||||||||||

| Cooling air volume | m3/h | 1000 | 2000 | 3000 | 5000 | 7500 | 9500 | 14000 | 18000 | 24000 | 28000 | 38000 | 50000 | |

| import and export | Pipe diameter | I | G1/2〃 | G3/4〃 | G3/4〃 | G1〃 | G1-1/2" | G1-1/2" | G2〃 | G2〃 | G2-1/2" | G2-1/2" | G3〃 | G3〃 |

| Security protection | Compressor overheat protection, overcurrent protection, high and low pressure protection, overtemperature protection, flow protection, phase sequence/phase loss protection, exhaust overheat protection, and antifreeze protection. | |||||||||||||

| Dimensions | long | mm | 600 | 750 | 945 | 1035 | 1475 | 1475 | 1800 | 1960 | 2080 | 2080 | 2300 | 2500 |

| Width | mm | 400 | 450 | 550 | 610 | 715 | 715 | 890 | 940 | 1000 | 1000 | 1220 | 1400 | |

| high | mm | 940 | 1100 | 1370 | 1385 | 1695 | 1695 | 1880 | 1960 | 2055 | 2055 | 2310 | 2310 | |

| Unit weight | KG | 60 | 85 | 130 | 170 | 300 | 350 | 520 | 590 | 790 | 880 | 1100 | 1350 | |

Note:

1. Refrigeration capacity is based on: chilled water inlet and outlet temperatures 12°C/7°C, condensing temperature 40°C (nominal refrigeration capacity)

2. Working range: Chilled water temperature range: 5℃~35℃; Chilled water inlet and outlet temperature difference: 3℃ to 8℃ Control accuracy ±1℃~±2℃

3. Use in an environment with an ambient temperature not higher than 35°C and ensure good ventilation

4. The above parameters are standard model parameters, please call us if you have any questions! We reserve the right to change the above parameters or dimensions without prior notice.

Anti-explosion Certificate