- Product Detail

- Product Tags

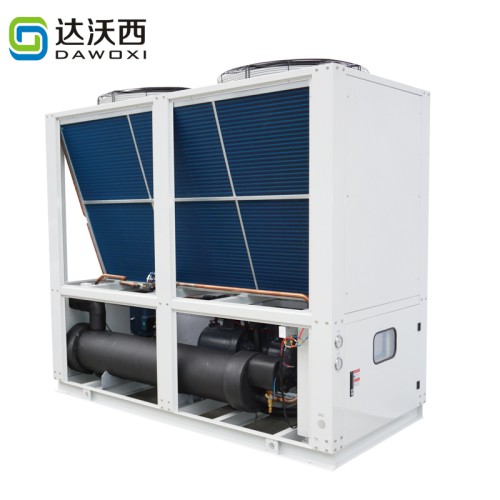

Cascade refrigeration unit (-40℃ ~-80℃ )

Product Overview

Cascade refrigeration is widely used in the heat treatment process of industrial products and the cold treatment of metals. It is widely used in military industry, aviation, aerospace, chemical industry, medicine, machinery manufacturing and other industries. Some process reactions require deep cold environment below -50℃. In order to ensure the reaction conditions, the reaction system is often cooled to -60℃ or even lower, and corresponding refrigeration and cooling measures must be taken.

Cascade refrigeration has a lower temperature, so the design of chillers, industrial chillers, freezers, and screw chillers is quite different from that of conventional units. The basic difference is that the binary cascade ultra-low temperature refrigeration equipment uses R22 as the front-stage cycle and R13 as the back-stage cycle. With a semi-closed screw or piston compressor as the main machine and alcohol as the refrigerant, it can produce a low temperature of -30°C~-80°C. The equipment is divided into two models with or without a box. Users can choose different powers and models according to actual usage. Our equipment has been filled with refrigerant or debugged before leaving the factory, so it is extremely convenient for users to use.

Unit characteristics

1. Wide temperature range: -40℃ or -120℃, temperature control accuracy ±1℃

2. Refrigeration capacity: 1 to 100KW available, customized according to your company's process requirements

3. Use international brand BITZER Germany (Bitzer) Taiwan HANBELL (Hanbell) high-efficiency energy-saving compressors matched with high-quality condensers and evaporators, with high efficiency, high performance, stable stability, low noise and long service life.

4. Industrial-grade PLC unit centralized control, with the energy ratio of the compressor, can timely and accurately control the matching of the unit's refrigeration capacity and cooling load, ensure the high-efficiency operation of the unit, and reduce operating costs. Optional RS485 and R232 interfaces can communicate with the computer to accept computer settings, control and transmit the measured temperature to the computer

5. The transmission pump adopts a magnetic pump, which has no leakage, no pollution and high lift.

6. Multiple alarm protections: water outage, water temperature too high, circulation pump failure, compressor overheating, pressure too high, overcurrent, phase loss, phase continuity, etc.

7. Heat dissipation method: air cooling and water cooling are optional, and the air-cooled condenser can be placed outdoors.

The company provides on-site selection in the early stage to assist customers in choosing the appropriate machine model and process planning.

We design and produce all kinds of non-standard process chillers according to user's requirements. We can also provide turnkey projects such as installation, repair and maintenance of all kinds of process cooling engineering system facilities.

Remarks: Refrigerant

The refrigerant generally uses dichloromethane (boiling point 40℃, freezing point -95℃), alcohol (boiling point 78℃, freezing point -114℃), dichlorofluoroethane (boiling point 32℃, freezing point -103℃), trifluorodichloroethane (boiling point 28.7℃, freezing point -107℃), difluorochloroethane (boiling point -10℃, freezing point -131℃), which are non-toxic, non-flammable, environmentally friendly and inexpensive. The circulation of the refrigerant uses a magnetic circulation pump to reduce pollution and the impact of low temperature on the bearing seal.

Note: Low temperature cascade (cascade refrigeration) is a non-standard refrigeration unit. Please call the sales staff for details.

Cascade refrigeration system flow chart

Technical parameter table of cascade refrigeration unit

| model | DWX-35CD | DWX40-CD | DWX45-CD | DWX55-CD | DWX-75CD | DWX-100CD | DWX-110CD | ||

| Cooling capacity | -45~-50℃ | KW | 34.9 | 40.1 | 45.3 | 54 | 74.8 | 98.1 | 106.8 |

| -55~60℃ | 22.5 | 25.9 | 29.4 | 3.7 | 52.2 | 68.5 | 74.6 | ||

| -65~70℃ | 13.5 | 17.4 | 19.4 | 24.2 | 33.6 | 44.1 | 48 | ||

| power supply | 3PH 380V50Hz 200V/220V/415V 50Hz(60Hz) | ||||||||

| Power distribution | KW | 35 | 45 | 52 | 70 | 90 | 105 | 115 | |

| Large operating current | A | 70 | 90 | 105 | 140 | 180 | 210 | 230 | |

| First stage compressor | power | KW | 17.7 | 19.4 | twenty three | 35.9 | 45.6 | 51 | 59.7 |

| refrigerant | - | R404A | |||||||

| Startup method | - | Direct Start | Y-△ | ||||||

| Two-stage compressor | power | KW | 16.35 | 1.2 | 21.1 | 25.2 | 33.2 | 41.6 | 45.6 |

| refrigerant | - | R23 | |||||||

| Startup method | - | Partial coil start | Y-△ | ||||||

| Condensation evaporator | Type | - | Plate heat exchanger/shell and tube heat exchanger | ||||||

| Evaporator | Type | - | Plate heat exchanger/shell and tube heat exchanger | ||||||

| Refrigerant flow | m3/h | 15 | 17.2 | 19.4 | 23.1 | 32.1 | 42 | 45.8 | |

| Condenser | Type | - | Shell and tube heat exchanger (water-cooled heat dissipation) | ||||||

| flow | m3/h | 11.8 | 13.5 | 15.3 | 19.7 | 26.3 | 32.7 | 36.4 | |

| Security protection | Compressor overheat protection, overcurrent protection, high and low pressure protection, overtemperature protection, flow protection, phase sequence/phase loss protection, exhaust overheat protection, and antifreeze protection. | ||||||||

| Take over specifications | Condenser | mm | DN40 | DN50 | DN50 | DN65 | DN65 | DN80 | DN80 |

| Evaporator | mm | DN50 | DN50 | DN65 | DN65 | DN80 | DN80 | DN80 | |

| Dimensions | Length (L) | mm | 1980 | 2180 | 2450 | 2610 | 2700 | 3000 | 3250 |

| Width (W) | mm | 1000 | 1000 | 1100 | 1100 | 1200 | 1100 | 1300 | |

| High (H) | mm | 1650 | 1700 | 1700 | 1750 | 1750 | 1800 | 1850 | |

| weight | net weight | KG | 860 | 1053 | 1323 | 1685 | 1860 | 2280 | 2880 |

| Operating weight | KG | 970 | 1180 | 1450 | 1896 | 2046 | 2580 | 3200 | |

| Cascade cryogenic refrigeration unit technical parameter table | |||||||||

| model | unit | DWX-130CD | DWX-145CD | DWX-170CD | DWX-180CD | DWX-190CD | DWX-210CD | DWX-230CD | |

| Cooling capacity | -45~-50℃ | KW | 130.2 | 142.9 | 168.4 | 177.9 | 194.6 | 210.7 | 232 |

| -55~60℃ | 90.9 | 99.8 | 117.6 | 124.2 | 135.9 | 147.1 | 162 | ||

| -65~70℃ | 58.6 | 64.3 | 75.7 | 80 | 87.5 | 94.8 | 104.3 | ||

| power supply | 3PH 380V50Hz 200V/220V/415V 50Hz(60Hz) | ||||||||

| Power distribution | KW | 130 | 150 | 160 | 170 | 190 | 210 | 240 | |

| Large operating current | A | 260 | 300 | 320 | 340 | 380 | 420 | 480 | |

| First stage compressor | power | KW | 67.1 | 76.4 | 80.3 | 88.3 | 96.1 | 105.2 | 124.3 |

| refrigerant | - | R404A | |||||||

| Startup method | - | Y-△ | |||||||

| Two-stage compressor | power | KW | 55.6 | 60.5 | 68.2 | 71.7 | 78.9 | 86.1 | 95.7 |

| refrigerant | - | R23 | |||||||

| Startup method | - | Y-△ | |||||||

| Condensation evaporator | Type | - | Plate heat exchanger/shell and tube heat exchanger | ||||||

| Evaporator | Type | - | Plate Heat Exchanger | ||||||

| Refrigerant flow | m3/h | 55.8 | 61.2 | 72.2 | 76.2 | 83.4 | 90.3 | 99.4 | |

| Condenser | Type | - | Shell and tube heat exchanger (water-cooled heat dissipation) | ||||||

| flow | m3/h | 43.4 | 48 | 54.3 | 57.9 | 63.4 | 68.9 | 77.5 | |

| Security protection | Compressor overheat protection, overcurrent protection, high and low pressure protection, overtemperature protection, flow protection, phase sequence/phase loss protection, exhaust overheat protection, and antifreeze protection. | ||||||||

| Take over specifications | Condenser | mm | DN80 | DN80 | DN100 | DN100 | DN100 | DN100 | DN100 |

| Evaporator | mm | DN100 | DN100 | DN100 | DN100 | DN100 | DN100 | DN100 | |

| Dimensions | Length (L) | mm | 3400 | 3600 | 3800 | 3800 | 4000 | 4100 | 4200 |

| Width (W) | mm | 1400 | 1500 | 1500 | 1500 | 1600 | 1600 | 1800 | |

| High (H) | mm | 1900 | 1900 | 2000 | 2000 | 2100 | 2100 | 2200 | |

| weight | net weight | KG | 3285 | 3480 | 3540 | 3600 | 3780 | 4140 | 4650 |

| Operating weight | KG | 3614 | 3600 | 3790 | 3970 | 4196 | 4580 | 5200 | |