- Product Detail

- Product Tags

Product Series

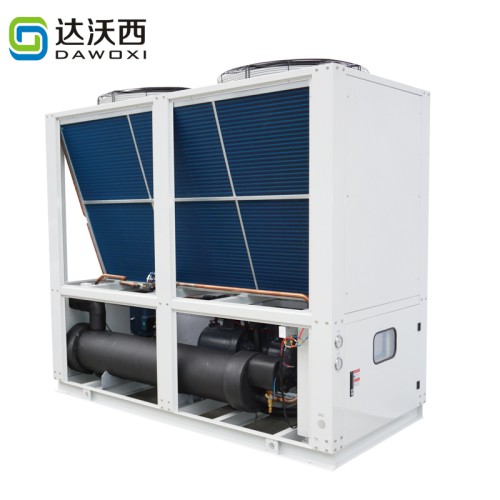

Model: DW-G-Series

Type: air-cooled/water-cooled

Cooling capacity range: 2.5KW~135KW

Temperature control accuracy: ±0.1℃~±1℃

Temperature range: -40℃~200℃

Number of channels: single channel/multi-channel

Customizable: Yes

Delivery time: 15 to 40 working days

With the upgrading of national industries, there are mandatory requirements for products in all walks of life. Especially in the new energy vehicles, motors, electronic controls, batteries, and electronic aerospace industries, Chinese companies are guided to advance into technological and cutting-edge products. This requires continuous verification of the reliability of various simulation tests on related materials, components, functional units, and systems. Correspondingly, the use of product testing equipment will increase significantly, and at the same time, it has also spawned reforms in testing processes. In order to simulate a wider temperature range, rapid temperature changes, higher temperature stability, and ensure the repeatability of experimental conditions, a higher standard temperature control system is required. The liquid energy temperature function system is a rapid refrigeration testing device produced under this environment.

Introduction of Dawoxi Temp Controller

The high and low temperature liquid cooling tester is a test device used to simulate extreme temperature environments and quickly and accurately control the temperature of the equipment under test (such as electronic components, batteries, chips, automotive parts, etc.). It combines liquid cooling technology and high and low temperature control systems, and can achieve rapid temperature rise and fall, high-precision temperature control, and long-term stability testing. It is widely used in scientific research, industrial production, and quality inspection.

Core composition and working principle

1. Liquid cooling circulation system

Use a circulating pump to drive the coolant (such as ethylene glycol aqueous solution, silicone oil or special refrigerant) through the device under test or test chamber, and use the high heat capacity and high thermal conductivity of the liquid to achieve efficient heat exchange.

Liquid cooling is more efficient than traditional air cooling and is suitable for scenarios with high power density or requiring rapid temperature changes.

2. Temperature control module

Refrigeration system: uses compressors, expansion valves, etc. to achieve low temperatures (e.g. -70°C to -40°C).

Heating system: high temperature (e.g. +100°C to +200°C, or even higher) is achieved through electric heaters.

PID control algorithm: **Adjust the cooling/heating power to ensure small temperature fluctuations (e.g. within ±0.5℃).

3. Control system

Touch screen or software interface, supports customized temperature curve (step change, cycle test, program controllable test, fixed value test, etc.).

Real-time monitoring of temperature, flow, pressure and other parameters, with alarm and protection functions (such as over-temperature, over-current, low liquid level).

4. External interface

Adapt to different test fixtures, support multi-channel fluid connection, and be compatible with devices of various sizes and shapes

Key performance parameters

Temperature range: Typical range -40 ℃ to +85 ℃, some devices can reach -90 ℃ to +250 ℃.

Cooling capacity: from several hundred watts to several tens of kilowatts (such as 10kW , 50kW , etc.) according to demand.

Flow control: adjustable flow range (such as 5~50L/min ).

Response speed: Heating and cooling rate can reach 5~10 ℃ /min

Precision control: temperature stability ± 0.1~0.5 ℃, flow fluctuation within ± 0.2L , pressure fluctuation accuracy ± 0.1bar.

Core advantages

1. Efficient thermal management

The heat transfer efficiency of liquid cooling is dozens of times that of air, which is suitable for heat dissipation and temperature control testing of high-power devices (such as electric vehicle batteries, motors, and electronically controlled IGBT modules).

2. Wide temperature range and fast response

It can simulate harsh environments such as extreme cold, high temperature, and rapid temperature changes to accelerate product aging testing or performance verification.

3. Precision control and repeatability

Supports programmed temperature control curves to ensure consistent test conditions, suitable for reliability tests (such as thermal shock tests).

4. Energy saving and low noise

Compared with traditional air cooling, liquid cooling systems consume less energy and make less noise during operation.

5. High compatibility

Adapt to the needs of different industries, such as chip packaging and testing, energy storage systems, aerospace components, etc.

Typical application scenarios

1. New Energy Vehicles

High and low temperature cycle testing of power battery packs, and verification of fast charging and heat dissipation performance.

Thermal management testing of motor controllers.

2. Semiconductors and Electronics

Chip ( CPU/GPU ) thermal performance test.

Performance verification of 5G base station and server liquid cooling systems.

3. Energy storage and energy

Thermal runaway prevention test for energy storage battery modules.

Temperature adaptability assessment of photovoltaic inverters.

4. Aerospace

Reliability testing of airborne equipment under extreme temperatures.

Basic parameters of high and low temperature liquid cooling test machine

| High temperature liquid constant temperature system (0··100) | |||||||||

| Performance parameter table | |||||||||

| Model | G-1AF | G-2AF | G-3AF | G-5AF | G-7AF | G-10AF | G-12AF | ||

| External load capacity | W | 2000 | 5000 | 6500 | 10000 | 18000 | 20000 | 25000 | |

| KCAL | 1720 | 4300 | 5590 | 8600 | 15480 | 17200 | 21500 | ||

| **Operating power | kW | 3 | 4 | 6 | 12 | 18 | twenty one | 28 | |

| **Operating current | A | 10 | 12 | 18 | 36 | 54 | 62 | 84 | |

| **Operating temperature | ℃ | 100 | |||||||

| **Operating temperature | ℃ | 0 | |||||||

| Temperature stability accuracy | ℃ | **0.1 | **0.2 | ||||||

| **Liquid supply pressure | Mpa | 0.4 | |||||||

| Liquid supply pressure stability accuracy (optional module) | Mpa | 0.01 | |||||||

| Minimum circulation | L/MIN | 0.9 | 18 | ||||||

| **Circulation volume | L/MIN | 1 | 100 | ||||||

| Flow stability control accuracy (optional module) | L/MIN | 0.1 | |||||||

| Using Power | 1PH-220V+N+PE-50HZ | 3PH-380V+N+PE-50HZ | |||||||

| Cold end power | Type | Single machine single stage | |||||||

| quantity | 1 | ||||||||

| Startup method | Direct Start | ||||||||

| power | KW | 0.6 | 1.1 | 2.2 | 3.7 | 7.5 | 8.5 | 11.0 | |

| Liquid drive source | form | High temperature centrifugal pump | |||||||

| Startup method | Direct Start | ||||||||

| power | KW | 0.37 | 0.55 | 1.1 | 2.2 | 2.4 | 3.0 | ||

| refrigerant | name | R-407C/404A | |||||||

| Control method | Multi-level linkage | ||||||||

| Filling amount | KG | 0.5 | 0.8 | 1.8 | 3.0 | 6.0 | 7.2 | 9.0 | |

| Heat Source | form | electro-thermal | |||||||

| Control method | Intermittent intervention | ||||||||

| Material | Stainless steel | ||||||||

| Energy storage capacity | KW | 2 | 6 | 9 | |||||

| Interface | Wire connection | ||||||||

| Cold source | Type | Stainless steel heat exchange tube | Stainless steel plate | ||||||

| Control method | Constant temperature joint adjustment | ||||||||

| Drive source | R22 | ||||||||

| Steady-state energy storage | W | 500 | 900 | 1800 | 3100 | 6250 | 7500 | 9300 | |

| Interface | Wire connection | ||||||||

| Heat dissipation | Type | High efficiency internal thread copper tube fin type | |||||||

| Control method | Pressure joint control | ||||||||

| Process form | Mechanical compression tightening | ||||||||

| Heat exchange capacity | KW | 3.2 | 6.0 | 12.0 | 20.0 | 40.0 | 48.0 | 60.0 | |

| Heat exhaust fan | Type | Low noise axial flow (low noise outer rotor fan) | |||||||

| quantity | 1 | 2 | |||||||

| diameter | MM | 250 | 400 | 450 | 600 | 500 | 550 | 600 | |

| Air volume | M3/H | 1000 | 1650 | 3300 | 5500 | 11000 | 13200 | 16000 | |

| Power | KW | 0.18 | 0.32 | 0.37 | 0.75 | 0.85 | 1.1 | 1.5 | |

| Internal system volume | L | 15 | 38 | 60 | |||||

| Main protective devices | Refrigerator high pressure protection, refrigerator low pressure protection, refrigerator overcurrent protection, low temperature protection, overtemperature protection, flow protection, phase sequence/phase loss protection, refrigerator overheat protection, circulation circuit overpressure protection, liquid replenishment tank replenishment warning, liquid drive pump overcurrent protection, | ||||||||

| Dimensions | Length L | mm | 600 | 750 | 900 | 850 | 1450 | 1690 | 1850 |

| Width | mm | 460 | 610 | 650 | 680 | 780 | 820 | 890 | |

| High H | mm | 1350 | 1450 | 1450 | 1750 | 1670 | 1690 | 1690 | |

| Unit Weight | kg | 110 | 150 | 260 | 370 | 620 | 670 | 810 | |

| 1) External load capacity refers to the full system output capacity per hour. Please request the corresponding data separately for non-full system load | |||||||||

| 2) The above parameters are for vehicle antifreeze at -25℃ | |||||||||

| 3) The above data are for air cooling units | |||||||||